MATOlog

Our technology is part of sustainable construction

Benefits of technology

Cost-effective and easy-to-install wireless technology enables long-term OnLine measurement of structures and surfaces. The facilities and structures are connected to OnLine monitoring, which creates visibility into the property’s humidity-technical functionality during construction and use of the property.

In the construction industry, our technology is part of humidity and temperature management, optimizing construction schedules and avoiding poor quality costs.

Roads and land areas are connected to OnLine monitoring, which enables preventive maintenance and informing of, e.g. slipperiness or flooding of the area.

Allows studying of humidity behaviour of materials as part of product development, e.g., the effect of concrete casting curing chemicals on water evaporation from capillary pores.

Analytics can be used to process measurement data for a variety of different purposes.

Measurement technology

MATOlog’s measurement technology is based on a combination of electronics and materials technology. The sensors use piezo resistive measurement technology combined with the probe and structure developed by MATOlog.

The developed structure makes it possible to measure capillary forces inside the structures. The technology can be used for a wide range of applications and withstands very stressful conditions, such as immersion in concrete. The sensors are completely dustproof.

Measurement and transmission consume very little energy, which makes it possible to manufacture various long-life wireless sensors. The battery integrated in the circuit board lasts up to ten years. No external power supply or battery required.

The frequency of the measurement and transmission intervals can be adjusted as desired or dynamically controlled as conditions change.

Data transmission

The sensors we manufacture operate in a wireless IoT network (LoRaWAN). In Finland, the national IoT network is operated by Digita Oy, whose network already covers almost entire Finland.

If necessary, the network can be amplified by a local base station, e.g. on construction sites. The network allows small amounts of data to be transferred very cost-effectively over long distances.

MATOlog sensors send raw data via the IoT network to the cloud service, where the data is processed to suit each need. The processed data is always available in the web interface.

Through API interfaces, data can be easily integrated into the company’s own information management systems.

Analytics

Data sent by MATOlog sensors is processed in the cloud service.

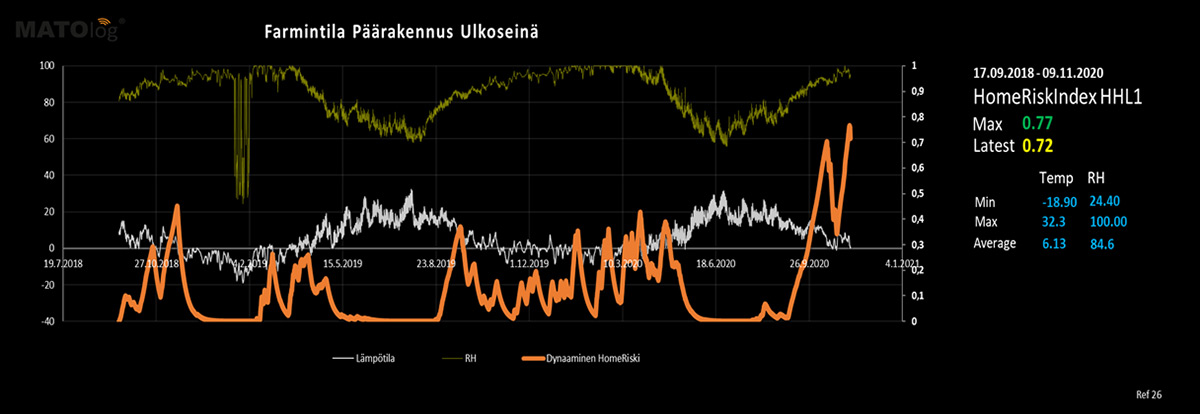

Data and algorithms are used to generate various mathematical models to generate added value.

- Making a strength assessment of curing concrete

- Concrete curing index

- Prediction of structure drying

- Mould risk identification

- Defining slipperiness

- Etc...